New moves for powerful plastic

Steel-strength plastic may soon bend to industry demands.

Steel-strength plastic may soon bend to industry demands.

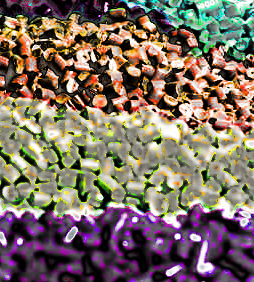

A team of researchers at the University of Oxford has developed innovative ways to simplify the processing of ultra-high molecular weight polyethylene (UHMWPE), a plastic prized for its remarkable strength and durability, which is often compared to steel.

A new study, published in Industrial Chemistry & Materials, addresses long-standing challenges in handling the material, paving the way for broader industrial use.

UHMWPE stands out among engineering plastics due to its high molecular weight, measured in the millions of Daltons, which gives it extraordinary tensile strength, impact resistance, and a self-lubricating quality.

These characteristics make it a material of choice for aerospace, biomedical, maritime, and ballistics applications.

However, its complex molecular structure leads to significant entanglements, resulting in extremely high melt viscosity - a feature that renders conventional processing methods, such as injection moulding, impractical.

Professor Dermot O’Hare, who spearheaded the research, says that these entanglements have been a “chief limiting factor” in fully realising UHMWPE’s potential.

The researchers tackled the issue through a series of novel approaches designed to untangle and modify the polymer’s structure.

These included tweaking the catalysts used in production to reduce molecular entanglements and introducing chain modifiers to adjust the polymer’s weight distribution.

Another effective strategy involved blending UHMWPE with high-density polyethylene (HDPE), which improved its flow characteristics while retaining its sought-after properties.

The team also discovered that adding small molecules could enhance processability without sacrificing strength, offering promising solutions for scaling up its industrial use.

The work holds significant promise for expanding UHMWPE’s application range, including its integration into advanced composite materials.

“These approaches and combinations thereof are considered crucial to expanding the applicability of UHMWPE,” O’Hare noted.

Beyond current uses, the findings also suggest possibilities for improving recycling methods and creating new materials with unprecedented properties.

Print

Print